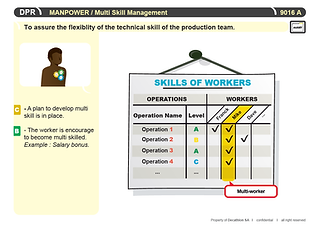

MULTISKILL MANAGEMENT

SKILL MATRIX TO ENCOURAGE

SKILL DEVELOPMENT

1. LEARN BY YOURSELF & CHALLENGE YOUR WAY OF DOING

WHY

Multiskill management ensure teammates satisfaction and contribute to stable process

WHAT

Skill management is the adequacy between individual teammates wishes and Project needs. Need of competencies comes from the project. Competencies are split into smaller skills (tasks). To support multiskill management we implement the skill matrix tool. It is a living tool the provides an accurate picture of the skill level of the team, being regularly updated. Before you begin to assess the skill level of an operator on a workstation, it is necessary to define a standard work for this workstation. Learning are systematically based on SOP (Standard Operating Procedure).

Generally we classify multiskill levels by 4 steps:

-

Level 1: Teammates is a trainee supported by a referents (level 4) at the training center. He does not work alone an the workstation. He applies the the SOP and safety rules.

-

Level 2: Teammates is self-sufficient and can even work on the production line. He ensures the quality "right at the first time"

-

Level 3: In addition to safety and quality, the teammates is autonomous on the production line. He complies with the standard time.

-

Level 4: The teammates becomes a referent. He has trained another teammates successfully. He has pedagogical skills and know-how to coach others. Be aware that teammates who have not practice a skill for a long time may have "lost their habits", and forgot basics requirements. Rules of revision of a level must be defined. So after a time, a new skill evaluation is needed.

HOW

-

Identify competencies needed for the Project

-

Split competencies into smaller skills (tasks), which are matching with a SOP

-

Define your skill validation process

-

Integrate core competencies (Strategic competencies) by validation of level 4

-

Identify and make visual critical skills (high skills, safety risks, long time to master)

-

Define the target of number of level 3 per critical skill to stabilize the process

-

Create and display the skill matrix to manage necessary resources to support your project

-

Set individual training plan & challenge it regularly. A training plan is attached to the skill matrix

-

There is a planning of rotation to push operators to practice multiskill

-

Debrief and update regularly the evolution of the team skills by a (visual) indicator

BENEFITS

-

Support the teammates satisfaction by developing their skills for better career path

-

Ensure stability & flexibility to the process

-

Increase the global view of the process & the product. Develop interest of the daily job (avoid boredom)

-

Ensure safety by avoiding repetition (musculoskeletal disorders), quality and efficiency

-

For each teammates, to get clear view of its competency level

-

Evaluate the global team competency level and determine the training priorities to ensure stable performances

2. COPY & IMPROVE ASSOCIATED BEST PRACTICES

Practice from: TEC factory

Contact: Jenny Yang

What: Multiskill matrix display

Gains: to use skill matrix as a daily tool management

Assessment level: Opex E8, from E to D

3. GO FURTHER WITH OUR COACHING OFFER

Please contact:

4. VALIDATE YOUR SKILLS

Competency = to promote the Comptency management (CIEC)

5. EVALUATE YOUR ORGANIZATION

Assessment = OPEX

Chapter = E8