ANDON SYSTEM

A USEFUL PROBLEM DETECTION TOOL AND TO REACT IMMEDIATELY

WHAT

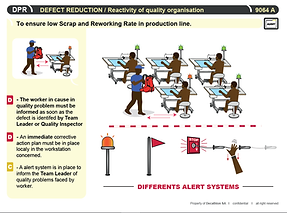

A famous system to alert and stop the production immediately is the Andon system. An Andon accelerates the information flow related to slowdowns and stops of the production system. Most famous is probably the Andon cord. This is a rope hanging from the ceiling. If the operator encounters a problem, he pulls the rope, which gives a signal to the Andon that there is a problem. Usually a second pull cancels the signal and tells the Andon that the problem is solved.

HOW

-

Design/define the more suitable solution for you organization in order to give the possibility to every teammates at every workstation to alert in real time the support team.

-

Put in place physically (could be digital / Hanging sytem / electronics...)

-

Train and coach people how to use this new system

-

Define reaction rules and apply

-

Challenge the system to continuously improve

BENEFITS

-

An Andon accelerates the information flow related to slowdowns and stops of the production system

-

Improve RFT

-

Solve directly problems before it turns big

1. LEARN BY YOURSELF & CHALLENGE YOUR WAY OF DOING

WHY

Problems identification is valuable. The art of problem solving is to detect them before they occurs. Reactions rules permit to anticipate problems and solve them before they turn big.

2. COPY & IMPROVE ASSOCIATED BEST PRACTICES

3. GO FURTHER WITH OUR COACHING OFFER

Please contact: TEC/AML Factory

4. VALIDATE YOUR SKILLS

Competency = To promote the 'problem detection' routines & tools [CIPD]

5. EVALUATE YOUR ORGANIZATION

Assessment = OPEX

Chapter = P3