top of page

MATERIEL AND INFORMATION

FLOW DIAGRAM

MFID

DMW CARD

1. LEARN BY YOURSELF & CHALLENGE YOUR WAY OF DOING

WHY

We set up the flow mapping tool (MIFA or VSM) Lean Manufacturing when "It's the mess in the workshop", when leaders does not know if it is well organized, they no longer visualizes the flow and does not know if his stocks are useful for production or if it hides a disorganization; the company no longer masters its lead time (flow time or customer satisfaction).

The company wants to lay out its industrial process and identify ways to improve. To make continuous improvement in accordance with the Lean Manufacturing process, it is necessary to target all unnecessary and non-value-added operations and attempt to reduce or eliminate them. It is necessary to know perfectly a process as well its physical part, as the information part. There must be a simple and understandable way for all staff.

WHAT

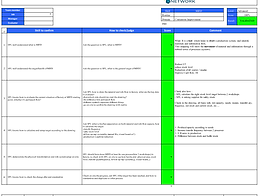

Value Chain Mapping (MIFA or VSM) is a graphical Lean Manufacturing tool that can be used to describe and map all information flows that characterize a process. See below an example.

HOW

MIFA stands for Material and Information Flow Analysis: Mapping the value chain. This flux mapping is used to:

- Visualize the value creation flow in the process.

- This mapping also serves Lean Manufacturing by discriminating value-added tasks from non-value-added tasks, and therefore identifying sources of wastage, and non-performance of the current process.

- To highlight flow organizations or stocks to enable their optimization in line with the Lean Manufacturing approach.

- It uses simple symbols (pictograms) whose knowledge allows an easy reading, an understanding of the process and the immediate identification of the points to be improved.

- According to the need during a diagnosis, this tool makes it possible to highlight in a graphic way a problematic or propositions of flow organization. The resulting Lean Manufacturing analysis optimizes the circulation of parts and information.

Value Chain Mapping (MIFA or VSM) identifies and visualizes using the MIFD (Material and Information Flow Diagram) the following points:

Material flows through the process by identifying:

- the stages of creation of diversity

- stagnation points (inter-process stocks)

- the mode of movement of products from one stage to another (means, personnel, frequencies, quantity)

Information flows by identifying:

- the origin and destination of the information

- the nature of the information (Kanban, program, sequence, ...)

- the mode of transmission used

Value chain mapping (MIFA or VSM) identifies the main barriers (above) to just-in-time production. The MIFD must highlight the geographical position (approximate) of the various processes of the studied site.

BENEFITS

Complete description of the flow, value-added analysis and lead time (or flow time) or inventory, and visual management tool to improve the flow, the MIFA is an essential tool in a Lean Manufacturing production system.

COPY & IMPROVE PRACTICES

2. COPY & IMPROVE ASSOCIATED BEST PRACTICES

OUR COACHING OFFER

4. VALIDATE YOUR SKILLS

Competency = to...

VALIDATE YOUR SKILLS

5. EVALUATE YOUR ORGANIZATION

Assessment = Opex

Chapter = O4

EVALUATE YOUR ORGANIZATION

SHARE WITH US

bottom of page